Technical Parameters of W-20 Webster Hardness Tester

Range | 0-20 HW (the equivalent of 20-110 HRE) |

Indicator Error | 0.5 HW (5 -17 HW) |

Repeatability Error | 0.5 HW (5 -17 HW) |

Weight | 0.5 kg |

Maximum specimen thickness | compare according to opening size and model |

Minimum sample inner diameter | compare according to the anvil size and model |

Accesorries of W-20 Webster Hardness Tester

1. Indenter

Crafted from imported specialty steel using advanced manufacturing techniques, the indenter delivers superior hardness and exceptional toughness. This results in an extended service life and excellent interchangeability. Each indenter is packaged in protective German-made packaging for comprehensive protection.

2. Indicator Hand

The high-strength pointer is highly resistant to bending or deformation, even after prolonged use or accidental mishandling, ensuring long-term accuracy.

3. Dial Glass

Made from high-strength, high-toughness glass, the dial window is highly resistant to breakage from impacts, providing durable protection for the gauge.

4. Handle

The handle is forged from aluminum alloy and undergoes anodic oxidation, resulting in a user-friendly grip that is highly wear-resistant and resistant to contamination.

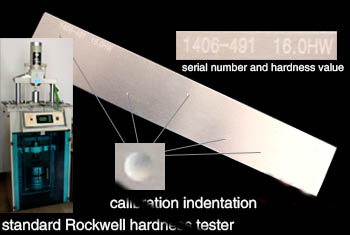

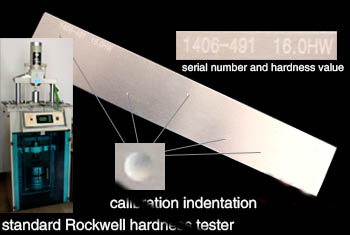

5. Hardness Blocks

Supplied with standard Rockwell hardness blocks, manufactured in strict accordance with metrological verification regulations. Hardness values are laser-etched for permanence, and all data is traceable within its validity period. Surface roughness and flatness fully comply with regulatory requirements.

6. High-quality

High-precision component processing, meticulous machine assembly, and rigorous quality inspection collectively ensure the instrument meets the highest standards of quality and performance.

7. Stability

Excellent stability across the entire measurement scale and at all calibration points. The pointer moves smoothly without any "sticking" or "crawling," guaranteeing reliable and consistent readings.

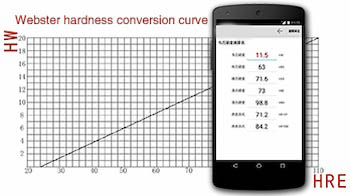

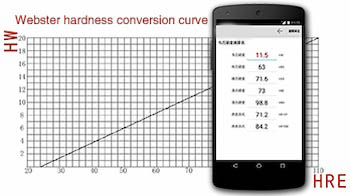

8. Conversion

A detailed hardness conversion table is provided in the product manual and via a dedicated "Hardness Conversion" application, enabling easy conversion of Webster hardness values to Vickers (HV), Rockwell (HRC, HRB), and Brinell (HB) scales.

9. Portability

The kit includes a high-quality portable case with custom-fit sponge cushioning. This design not only ensures excellent portability but also provides maximum protection for the instrument during transport and storage.

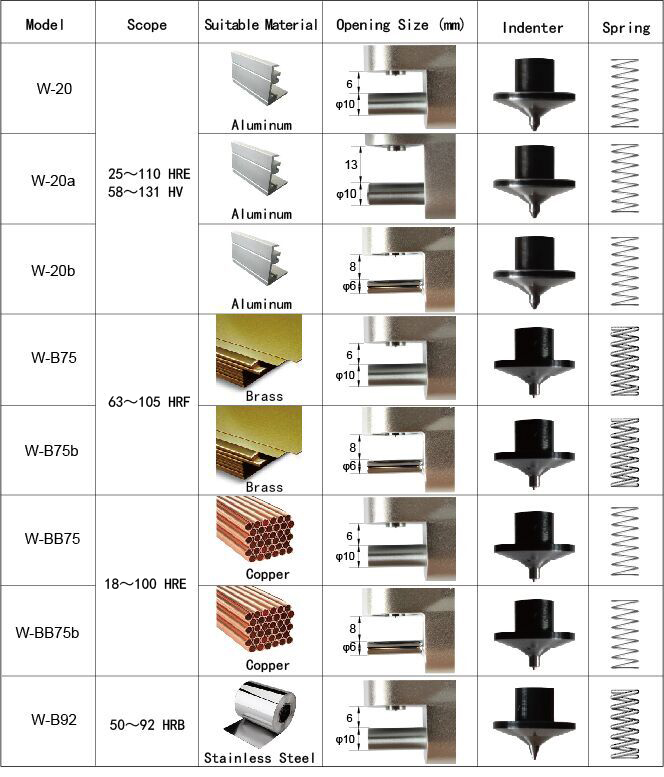

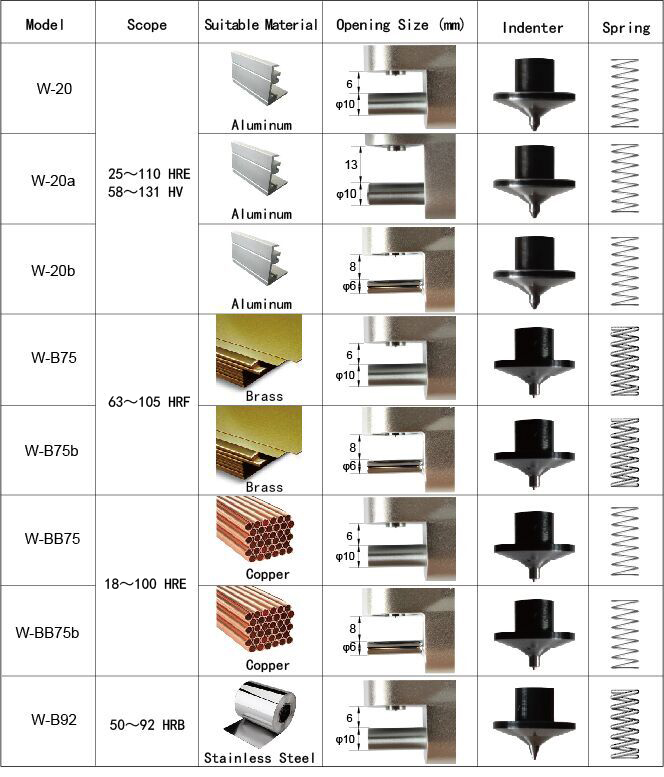

Comparison of W-20 Webster Hardness Tester

W-20 series include three models:

W-20 Webster hardness tester mainly use for inspect aluminum alloy, tube and plate.

W-20a can inspect industrial aluminum extrusions, plates or parts which have the thickness upper limit to 13 mm.

W-20b test small aluminum profiles or aluminum profiles pipes which have the inner diameter over 6 mm.

W-B75, W-BB75 Webster hardness tester inspects copper alloy, and W-B92 Webster hardness tester inspect stainless steel, especially suit for testing the hardness of materials such as mild steel, copper, brass.

MODELS

W-20 | Very popular model, used to inspect normal aluminum profiles. Working pieces requirements: Thickness 0.4-6mm,inner diameter>10mm. |

W-20a | inspect aluminum profiles with working pieces' thickness within 13 mm. |

W-20b | inspect aluminum tubing with working piece inner diameter over 6mm. |

WB75 | Inspect brass tubing and brass sheets. Woking piece thickness 0.4-6mm, inner diameter>10mm. |

W-B75b | Inspect brass tubing and brass sheets. Woking piece thickness 0.4-8mm, inner diameter>6mm. |

WBB75 | Inspect copper tubing and copper sheets. Woking piece thickness 0.4-6mm, inner diameter>10mm. |

W-BB75b | Inspect copper tubing and copper sheets. Working piece thickness 0.4-8mm,inner diameter>6mm. |

W-B92 | Inspect soft stainless steel sheets, cold-rolled steel, etc. Working piece thickness 0.4-6mm,inner diameter>10mm. |

Standard Delivery of W-20 Webster Hardness Tester

| STANDARD ASSEMBLY: |

| Tester |

| Standard hardness block |

| Spare indenter |

| Calibration wrench |

| Small screwdriver |

| Carrying case |

| Dial assembly |

Optional Delivery of W-20 Webster Hardness Tester

| OPTIONAL ACCESSORIES: |

| Indenter |

| Standard hardness block |

| Dial glass |

français

français Español

Español русский

русский العربية

العربية português

português