-

Products

- Force Gauge

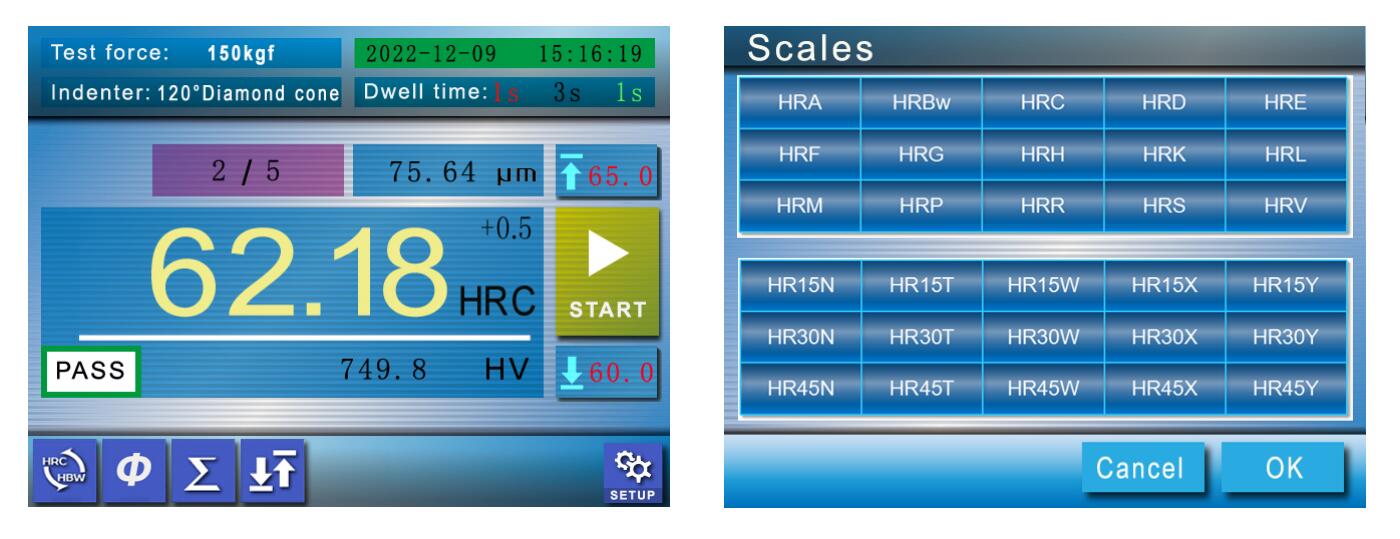

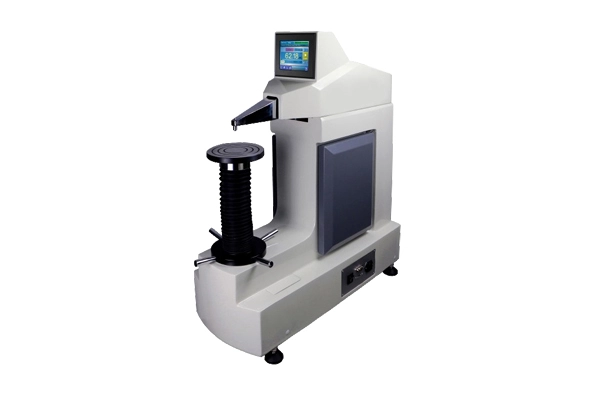

- Automatic Rockwell Hardness Tester

- Superficial Rockwell Hardness Tester

- Surface Roughness Tester

- Coating Thickness Gauge

- Ultrasonic Thickness Gauge

- Portable Leeb Hardness Tester

- Webster Hardness Tester

- Barcol Impressor Hardness Tester

- Shore Hardness Tester

- Flaw Detector

- Sterilizer and Distiller

- HP Force Gauge Test Stand

- Fruit Hardness Tester

- Digital Torque Meter

- Brinell Hardness Tester

- Vibration Tester

- CO2 Meter

- Portable Meters

- Blocks and Spare parts

- Test Types

- Application

- Company

- Services

- Contact Us

- Request A Quote

français

français Español

Español русский

русский العربية

العربية português

português