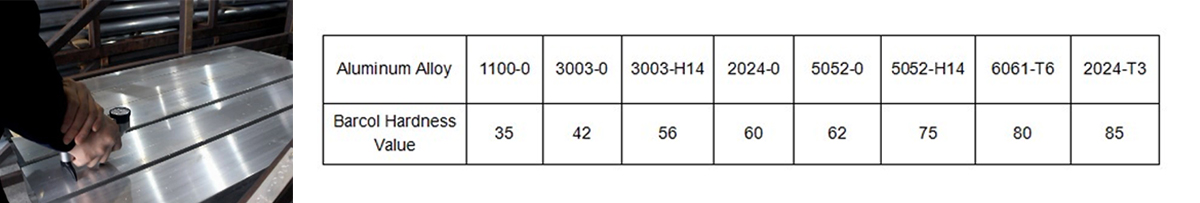

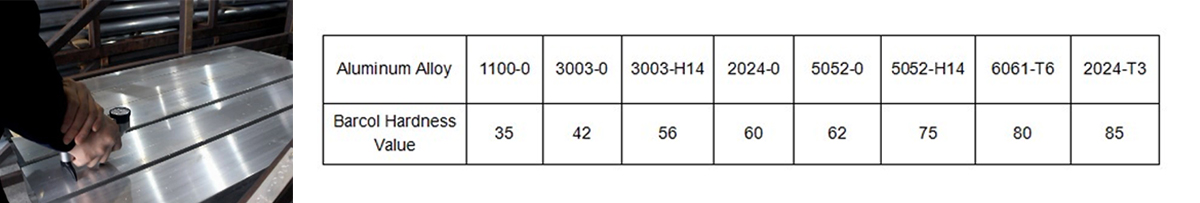

Application of 934-1 Barcol Hardness Tester

934-1 Barcol Impressor by Lanetech, a leading hardness tester factory,

Lanetech Barcol Impressor Series: Precision Hardness Testing for Diverse Materials

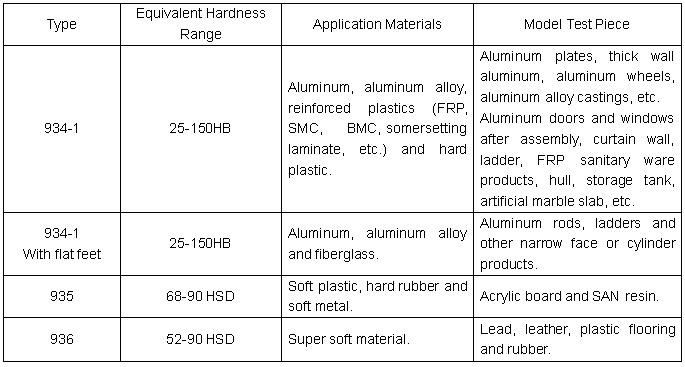

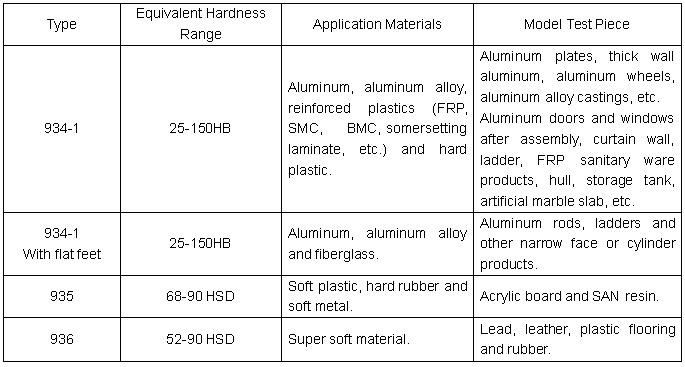

As a leading hardness tester manufacturer, Lanetech provides a specialized Barcol Impressor series for non-destructive hardness testing across industries. Each model is engineered for specific material groups to deliver accurate and reliable results.

Model 934-1: For Aluminum Alloys & Fiber Reinforced Plastics

The 934-1 Barcol Impressor is primarily used for testing aluminum and its alloys. It is suitable for a wide range of forms, including:

Pure aluminum and aluminum alloys

Thick aluminum sheets, plates, and bars

Assembled aluminum components (e.g., alloy doors, windows, and ladders).

It is also extensively used for testing fiber reinforced plastics and hard plastics in accordance with ASTM D2583. The 934-1 complies with ASTM B648-00, the standard test method for indentation hardness of aluminum alloys using a Barcol Impressor.

Complete Product Line for All Your Testing Needs;

Model 935: Ideal for testing soft plastics, lead, tin, and other soft metals;

Model 936: Designed for testing rubber, wood, leather, and similar materials;

Technical Parameters of 934-1 Barcol Hardness Tester

Testing Range | 0 - 100 HBa (equivalent to 25 - 135 HBW) |

Resolution | 0.5 HBa |

Indication Error | ±2 HBa (42 ~ 48 HBa);±1 HBa (81 ~ 88 HBa) |

Repeatability Error | ±2 HBa (42 ~ 48 HBa);±1 HBa (81 ~ 88 HBa) |

Weight | 0.5 kg |

Features of 934-1 Barcol Hardness Tester

1. Easy to Use & Highly Efficient

Engineered for true one-handed operation, the Barcol Hardness Tester is intuitive and requires minimal training. Its portable design enables rapid, high-efficiency testing anywhere—on the production floor, in the warehouse, or at the job site.

2. High Sensitivity with 100 Scales

Featuring a precise 100-scale measurement range, the Barcol Hardness Tester offers significantly higher sensitivity compared to Webster Hardness Testers, ensuring finer resolution and more detailed material assessment.

3. Wide Testing Range for Aluminum Materials

The tester covers a comprehensive range of aluminum materials, from soft pure aluminum to super hard aluminum alloys, providing versatile application across various production and quality control stages.

4. Precision Indenter for Long Life & Accuracy

The indenter is manufactured with special tool steel whose material hardness and dimensional tolerances strictly conform to the 2013 verification regulation and rigorous internal enterprise standards. Each indenter undergoes strict individual quality inspection to guarantee the long-term accuracy, long service life, and excellent interchangeability of the Barcol Hardness Tester.

5. Durable Screw Rod for Enhanced Reliability

A sophisticated metal screw rod mechanism ensures superior instrument life and reliability. This robust construction offers a significant advantage over other Barcol hardness testers in the market that use less durable plastic gears.

6. Certified Hardness Blocks for Accurate Calibration

Every Barcol hardness block is directly imported from the United States, guaranteeing the veracity, stability, and uniformity of all measurement results. This provides traceable confidence in your quality control data.

7. Robust Die-casting Case

The heavy-duty die-cast case is not only strong and aesthetically pleasing but also designed with an ergonomic grip for comfortable and secure handling during use.

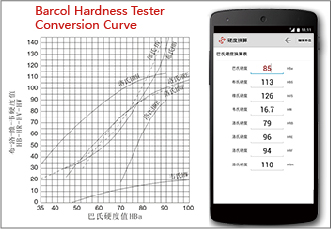

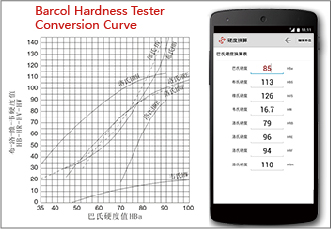

8. Comprehensive Hardness Conversion

Using the included Barcol hardness conversion table, values can be easily converted to Brinell (HB), Rockwell (HR), and Webster (HW) hardness scales. Additionally, Barcol values for rubber materials obtained with models 935 and 936 can be converted to Shore hardness values.

934-1 Barcol Impressor Type Comparison

Standard Delivery of 934-1 Barcol Impressor Hardness Tester

| Tester |

| 2 Spare indenters |

| Standard hardness block (high) |

| Standard hardness block (low) |

| Calibration wrench |

| Leg |

| Carrying case |

Optional Delivery of 934-1 Barcol Impressor Hardness Tester

| Spare indenters |

| Standard hardness block (high/low) |

| Dial glass |

| Flat leg |

français

français Español

Español русский

русский العربية

العربية português

português