TH520 Portable Lee Hardness Tester

TH520 Portable Leeb Hardness Tester | 6-Scale Workshop Tool with 7 Impact Devices

Compact on-site tester for workshop applications, featuring independent calibration per scale and multi-device compatibility. Very popular model.

Features of TH520 Portable Lee Hardness Tester

Smart Multi-Angle Hardness Tester | Built-In Printer & Auto-Calibration

*Industrial-Grade Device with 7 Auto-Detect Impact Heads & Batch Testing Solutions*

✅Core Advantages

✔️ 360° Freedom Testing – Works upside down/in narrow spaces with<0.1% angle error

✔️ Smart Auto-Calibration – Meets ISO/ASMT/JIS standards via start-value calibration

✔️ 7-in-1 Impact Device Hub – Automatic sensor recognition for welds/coatings/thin materials

✔️ Real-Time Batch QA – Tolerance-limit alarms + instant built-in thermal printing

✔️ 10hr Ultra Battery – Clear power indicator with fast USB-C charging

✅Technical Highlights

OEM-Ready System: Custom branding/software integration supported

Intelligent UI: One-touch material/hardness standard switching (HV/HRC/HB etc.)

Lifetime Service: 2-year warranty + free calibration protocols

Cost-Effective: 40% lower TCO vs traditional testers

✅Trust-Building Features

✅ Precision Guarantee – NIST-compliant available

✅ Factory Direct Savings – Eliminate middleman markup

✅ Crash-Proof Design – Military-grade shock absorption casing

Specifications of TH520 Portable Lee Hardness Tester

Measuring Range | 170-960HLD |

| Other measuring range | HRC(17.9~69.5), HB(19~683), HV(80~1042), HS(30.6~102.6), HRA(59.1~88),HRB(13.5~101.7) |

Measuring Materials | Steel and cast steel, alloy tool steel, stainless steel, gray cast iron, nodular cast iron, cast aluminum alloy, copper zinc alloys (brass), copper and tin alloy, copper (bronze), forged steel, |

Hardness Scale | HL, HB, HRB, HRC, HRA, HV, HS |

Display | 128*64 digital matrix LCD |

Accuracy | ±6HLD(when HLD=760+/-30) |

Display. Reading | Leeb, conversion hardness, material, impact direction, test times, average value, time |

Hardness Direction | 360° /down, inclined down, level, inclined up and up/ |

Memory | Max 600 groups (relative to impact times 1~32 adjustable) |

Applicable Workpiece | Min. Weight | 5 kgs |

2 kgs /on solid support/ |

0.1 kg /coupled on plate/ |

Min. Thickness | 5mm |

Min. Radius of curved surface | 30mm |

Max. roughness (Ra) | 1.6μm |

Power Supply | Rechargeable li-battery |

Weight | 0.6kg |

Dimensions | 210x85x45mm |

Standard Delivery of TH520 Portable Lee Hardness Tester

Main Unit | 1 pcs |

Impact Device D | 1 pcs |

Cleaning Brush | 1 pcs |

Small Support Ring | 1 pcs |

USB Cable | 1 pcs |

Hardness Test Block | 1 pcs |

User Manual | 1 pcs |

| PC Software | 1 pcs |

Instrument Case | 1 pcs |

| Warranty | 2 years |

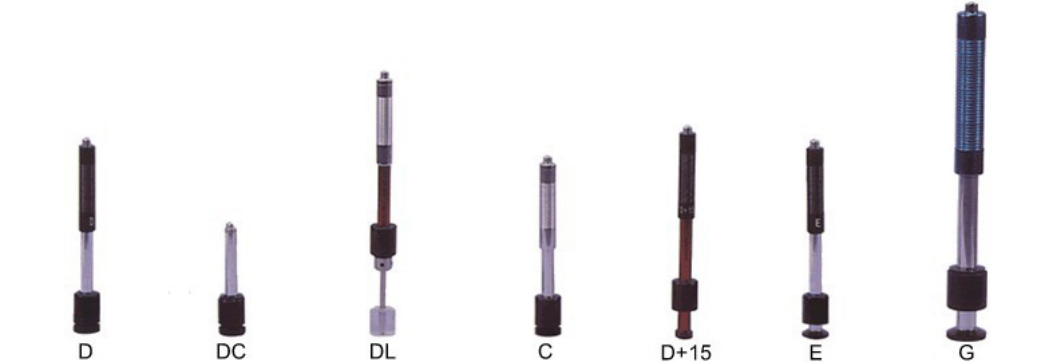

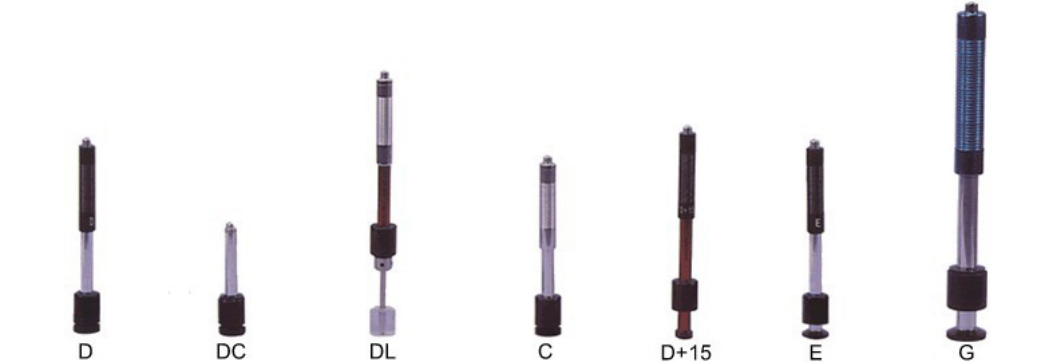

RELATED OPTIONAL ITEMS

Type of Impact Device | DC(D)/DL | D+15 | C | G | E |

Impacting energy Mass of impact body | 11mJ 5.5g/7.2g | 11mJ 7.8g | 2.7mJ 3.0g | 90mJ 20.0g | 11mJ 5.5g |

Test tip hardness: Dia. Test tip: Material of test tip: | 1600HV 3mm Tungsten carbide | 1600HV 3mm Tungsten carbide | 1600HV 3mm Tungsten carbide | 1600HV 5mm Tungsten carbide | 5000HV 3mm synthetic diamond |

Impact device diameter: Impact device length: Impact device weight: | 20mm 86(147)/75mm 50g | 20mm 162mm 80g | 20mm 141mm 75g | 30mm 254mm 250g | 20mm 155mm 80g |

Max. hardness of sample | 940HV | 940HV | 1000HV | 650HB | 1200HV |

Mean roughness value of sample surface Ra: | 1.6μm | 1.6μm | 0.4μm | 6.3μm | 1.6μm |

Min. weight of sample: Measure directly with stand Need coupling tightly | >5kg 2~5kg 0.05~2kg | >5kg 2~5kg 0.05~2kg | >1.5kg 0.5~1.5kg 0.02~0.5kg | >15kg 5~15kg 0.5~5kg | >5kg 2~5kg 0.05~2kg |

Min. thickness of sample Coupling tightly: Min. layer thickness for surface hardening: | 5mm ≥0.8mm | 5mm ≥0.8mm | 1mm ≥0.2mm | 10mm ≥1.2mm | 5mm ≥0.8mm |

Size of tip indentation |

Hardness 300HV | Indentation diameter: Depth of indentation: | 0.54mm 24μm | 0.54mm 24μm | 0.38mm 12μm | 1.03mm 53μm | 0.54mm 24μm |

Hardness 600HV | Indentation diameter: Depth of indentation | 0.54mm 17μm | 0.54mm 17μm | 0.32mm 8μm | 0.90mm 41μm | 0.54mm 17μm |

Hardness 800HV | Indentation diameter: Depth of indentation | 0.35mm 10μm | 0.35mm 10μm | 0.35mm 7μm | -- -- | 0.35mm 10μm |

Application | DC type used to measuring hole or inside face of cylinder, DL type used to measuring elongated narrow slot or hole, D type for routine measurements. | Suitable for measuring surface of the trench or concave. | Suitable for measuring thin workpiece and harden surface. | Suitable for heavy or rough castings and forgings. | Suitable high hardness material. |

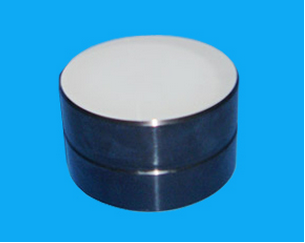

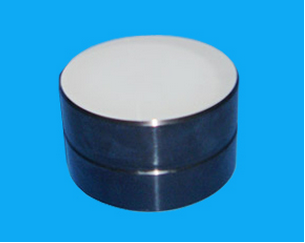

| Standard Hardness Calibration Block With high accuracy standard hardness value, use for calibration of leeb hardness tester. |

| Support Ring for Hardness Tester Suitable for difference measure situation, 12 pcs/ set |

| Connecting Cable for Hardness Tester and Probe |

| Thermal Printing Paper Suitable for mini thermal printer and Kaidas’s tester with built-in printer Packing: 10pcs/bag |

Related Portable Leeb Hardness Tester

français

français Español

Español русский

русский العربية

العربية português

português

.webp)

.webp)

.webp)