Steel is one of the most common materials tested using a Brinell hardness tester. This includes various types of steel such as carbon steel, stainless steel, and alloy steel. The Brinell hardness test can provide valuable information about the strength and durability of steel components.

-

Products

- Force Gauge

- Automatic Rockwell Hardness Tester

- Superficial Rockwell Hardness Tester

- Surface Roughness Tester

- Coating Thickness Gauge

- Ultrasonic Thickness Gauge

- Portable Leeb Hardness Tester

- Webster Hardness Tester

- Barcol Impressor Hardness Tester

- Shore Hardness Tester

- Flaw Detector

- Sterilizer and Distiller

- HP Force Gauge Test Stand

- Fruit Hardness Tester

- Digital Torque Meter

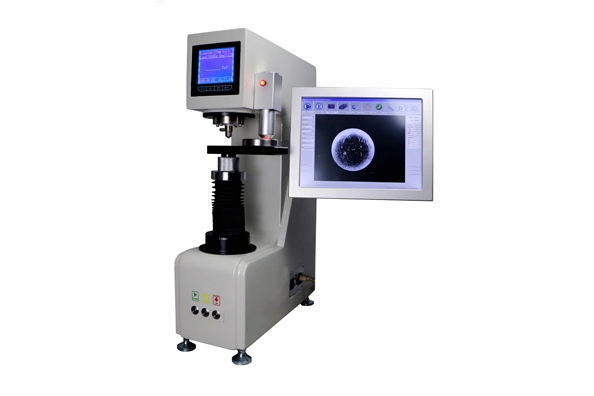

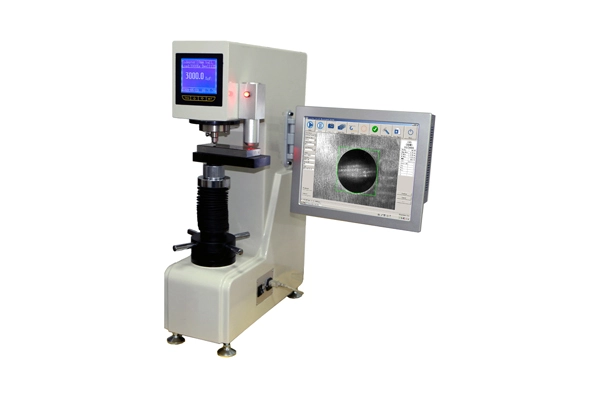

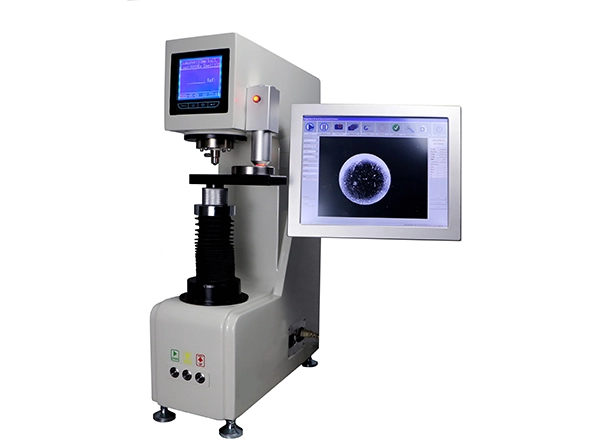

- Brinell Hardness Tester

- Vibration Tester

- CO2 Meter

- Portable Meters

- Blocks and Spare parts

- Test Types

- Application

- Company

- Services

- Contact Us

- Request A Quote

français

français Español

Español русский

русский العربية

العربية português

português